Hydraulic Pumps

- Share

EXCAVATOR HYDRAULIC PUMPS

The excavator is a construction machinery driven by a hydraulic system and has the characteristics of high efficiency, high precision and high reliability.

1. Working Principle

The hydraulic system is one of the most important components of an excavator. It is mainly composed of hydraulic pumps, hydraulic cylinders, hydraulic valves, fuel tanks, pipelines and other components. The hydraulic pump presses liquid into the hydraulic cylinder, allowing the hydraulic cylinder to make corresponding actions, such as lifting arms, telescopic arms, buckets, etc.

Among them, the hydraulic pump is an important source of power. It converts the discharged liquid into hydraulic energy through the transmission device and the power output by the engine. The hydraulic valve is a central component, responsible for regulating the steady-pressure fluid flow output by the hydraulic pump, adjusting hydraulic distribution according to working conditions and controlling the direction and operating force of the oil flow to realize various functions of the excavator.

A hydraulic cylinder usually consists of two pistons, which are filled with liquid. When the hydraulic pump inputs a certain pressure, the liquid is compressed, so the pressure increases and the hydraulic cylinder begins to move. The movement trajectory, rotation speed, angle, etc. of the hydraulic cylinder can be controlled by changing the pressure.

2. What Are Plunger Pumps and Gear Pumps?

Hydraulic pumps convert mechanical energy into liquid pressure energy. We generally see gear pumps and plunger pumps (for excavators and loaders).

What they have in common: They all create pressure on the liquid through volume changes.

Difference: different mechanism, different volume and location. The liquid volume of the gear pump is between the two gears, and the liquid volume is changed by the rotation of the gears. The volume of the plunger pump is in each plunger cylinder.

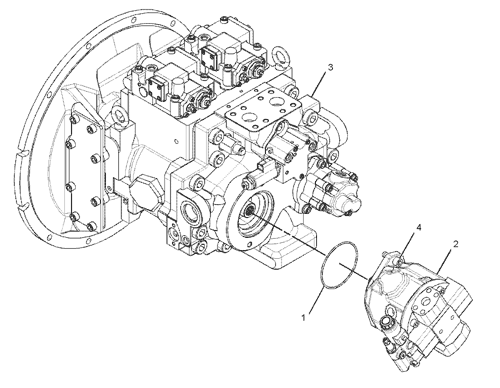

Common large and medium-sized excavators generally combine a plunger pump and a gear pump to form a hydraulic pump assembly. Generally, the main pump is a plunger pump (which outputs a large hydraulic oil pressure) to supply hydraulic travel motors, hydraulic swing motors, and hydraulic cylinders. oil; the pilot pump is a gear pump (the output hydraulic oil pressure is small) and supplies oil to the distribution valve.

Kawasaki's K3V pump is commonly used on excavators. The main pump of the excavator generally uses a double pump, with a rated pressure of 34MPA and an instantaneous maximum pressure of up to 39MPA.

The reason why the pump oil pressure of the plunger pump is higher than that of the gear pump is because its work and volume efficiency are higher. Currently, a large number of hydraulic excavators use swash plate variable axial piston pumps. They usually use double pumps, using a through shaft to connect two plunger pumps in series, so they are also called through shaft pumps. The through-shaft pump used on the excavator can also be connected to a small gear pump as a servo pump (that is, the pilot pump), which greatly simplifies the layout of the excavator.